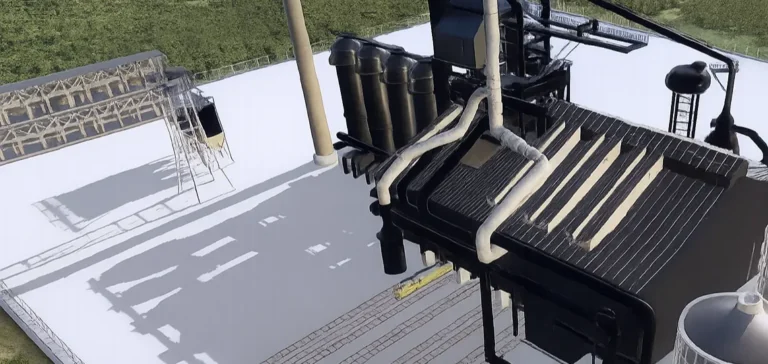

ArcelorMittal Brazil has partnered with Utility Global to explore the implementation of a clean hydrogen project at its Juiz de Fora industrial site in Minas Gerais. This partnership aims to assess the integration of the H2Gen system, a technology developed by Utility Global, within the Front-End Engineering and Design (FEED) process. The H2Gen system converts blast furnace gases into pure hydrogen and a concentrated stream of carbon dioxide (CO2), suitable for capture and storage.

H2Gen, a technology adapted to the steel industry

The patented H2Gen solution does not require electricity and converts variable industrial gases into high-purity hydrogen. The concentrated CO2 generated by the process simplifies subsequent capture and sequestration steps, which is a major challenge for the steel industry. According to figures published by Utility Global, the planned facility could produce up to 3 tons per day of hydrogen, directly from local steelmaking by-products.

The hydrogen produced would be recirculated into the steel manufacturing process, replacing the natural gas usually used. This technological choice should enable ArcelorMittal Brazil to reduce the carbon intensity of its operations while maintaining industrial performance at the site. The modular and scalable nature of the technology allows for gradual adaptation of production capacity.

Strategic investment and sector outlook

Utility Global is currently conducting technical and economic studies to validate the feasibility of deploying the H2Gen technology at the Brazilian site. At the same time, ArcelorMittal has invested $5mn in Utility Global through its XCarb Innovation Fund. Launched in 2021, this fund supports companies developing innovative solutions to reduce carbon emissions in steel production.

Irina Gorbounova, head of the XCarb Innovation Fund, stated that the fund’s objective is not only to invest in promising technologies but also to offer selected companies the opportunity to test their solutions within the group’s global industrial network. This approach, combining financial investment and access to infrastructure, is intended to accelerate the development of technologies designed to transform the steel industry value chain.

The operation at Juiz de Fora is one of the first examples of industrial application of the H2Gen process in the South American market. Utility Global’s management emphasises that this project is part of a growth strategy focused on industrial innovation and the competitiveness of heavy industry sectors.