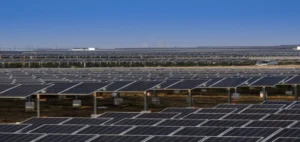

The independent power project Oman Manah-1, designed and built by Shanghai Electric, completed its first month of operation with results consistent with forecasts. This plant, with an installed capacity of 500 megawatts, is designed to generate 1.5 billion kilowatt-hours of electricity annually. According to published data, this output is expected to reduce carbon dioxide emissions by 780,000 tons per year. Operational indicators confirm performance levels in line with the technical expectations established at commissioning.

A structured industrial partnership

The project was carried out through a partnership between Shanghai Electric and Électricité de France (EDF). Responsibilities were divided between Chinese and Omani teams, with a clear allocation of tasks. Chinese engineers oversaw the design of the solar field, while local teams handled the construction of the substation. This “separate teams” strategy allowed the reconciliation of international standards with national regulations.

Shanghai Electric managed the entire value chain, from design and procurement to construction and long-term maintenance. This integrated approach promoted centralized process management, reducing fragmentation risks and improving technical consistency across the project.

Optimized construction management

The construction site was organized into eleven distinct sections, each independently managed to streamline project progress. This method reduced delivery times by 22% compared to the initial schedule. Operational data indicates that more than four million work hours were completed without accidents, supported by reinforced safety procedures. A dedicated digital application enabled the identification and resolution of 924 potential safety risks in real time.

Heavy equipment utilization was maintained at 90% of capacity, contributing to efficient resource use. In parallel, a cross-training policy for workers increased flexibility across construction areas, helping teams adapt to shifting needs during the build phase.

Accelerated timelines and technical innovations

The installation of medium-voltage cabling and terminals was completed in just 72 hours by a specialized team of twenty technicians. This achievement formed part of a broader effort to reduce timelines, further supported by the on-site presence of designers, which improved supervision efficiency by 30%.

Grid connection testing was carried out simultaneously across multiple zones, enabling integration into the national grid three weeks ahead of schedule. The project’s 59 sections were completed in nine days, achieving a 100% compliance rate with no material damage or workplace incidents reported.

Applied technologies and operational performance

The use of Chinese-designed high-voltage cables and enhanced pile supports reduced site leveling work by 80%. This innovation shortened the overall construction schedule by 60 days. Supply chain optimization, combined with precise procurement planning, ensured timely delivery, with equipment performance surpassing initial targets.

This combination of technology and project management methods positioned the Manah-1 project as a notable regional achievement in solar infrastructure, due to its rapid deployment and verified operational results.

Economic impacts and skills transfer

The project also incorporated a social and economic dimension through the mobilization of local resources. Published data indicates that 90% of the workforce dedicated to operations and maintenance is drawn from the Omani population. In parallel, technical training programs were integrated into the country’s vocational education system. This initiative aims to strengthen skills in the energy sector and facilitate the transfer of knowledge to the local workforce.

The Manah-1 project illustrates the convergence of structured technical management, industrial innovation, and international partnerships. These elements contribute to reinforcing regional energy security while developing sustainable local capacities.