TAE Technologies, a private company specialising in nuclear fusion, has announced a significant technical milestone in the development of its Field-Reversed Configuration (FRC) fusion technology. According to results published in the journal Nature Communications, this advancement is expected to improve reactor performance while substantially cutting operating and construction costs, potentially by up to 50%.

A simplified and more efficient device

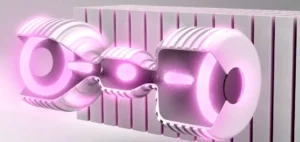

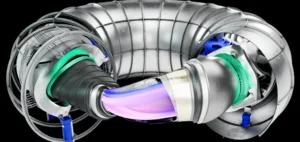

The system works by creating and stabilising a plasma – a superheated gas essential for fusion – without the need for complex formation sections or traditional configurations used in other fusion approaches such as tokamaks. TAE succeeded in producing a stable plasma using only Neutral Beam Injection (NBI), thereby eliminating quartz formation modules and the supersonic collision systems usually required.

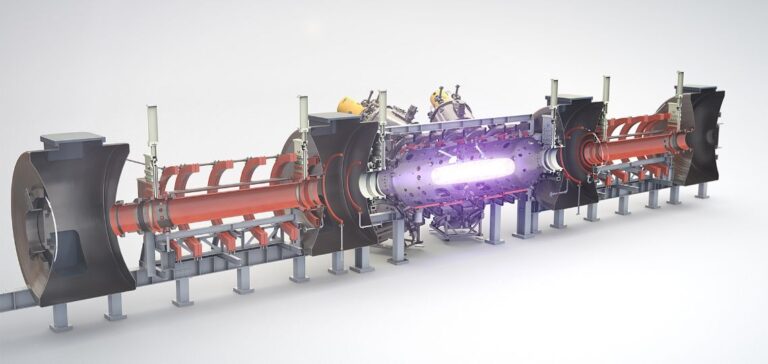

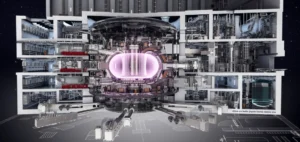

This new machine, named “Norm,” is more compact than the previous prototype “Norman.” It has achieved consistent steady-state performance, validating components and operational modes intended for integration into the company’s next-generation reactors, including “Copernicus.”

Optimised for commercial fusion

The exclusive use of NBI for both plasma creation and stabilisation marks a first in the field. It renders the FRC architecture more competitive with the economic constraints of commercial fusion. This method not only increases the system’s energy efficiency but also reduces the number of external magnets required, thereby lowering overall electricity consumption.

TAE’s technology also incorporates particle accelerators, customised power supplies and real-time control systems to eliminate plasma instabilities, long seen as a barrier to FRC viability. These innovations position the company among the few capable of advancing hydrogen-boron (p-B11) fusion, which is regarded as safer and easier to maintain.

Readiness for next-generation deployment

The Norm reactor marks a decisive step in TAE’s industrial roadmap, which anticipates demonstrating net energy gain with the Copernicus prototype before the end of the decade. This will be followed in the 2030s by “Da Vinci,” the first power plant prototype based on the company’s FRC approach.

Michl Binderbauer, Chief Executive Officer of TAE Technologies, stated that Norm now enables full control of the remaining critical elements of the FRC concept, paving the way for economically viable and scalable devices. Toshiki Tajima, Chief Science Officer, added that a pure NBI approach had never previously been demonstrated conclusively and that the breakthrough was enabled by TAE’s specific technical innovations.