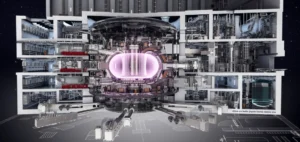

Shanghai Electric Group has announced new technological milestones in the field of controlled nuclear fusion, with the successful delivery of the world’s largest toroidal field coil case and the shipment of a magnet cold-test cryostat destined for the ITER project site in southern France. These developments highlight China’s growing capabilities in advanced nuclear engineering.

Components delivered for ITER and tested in France

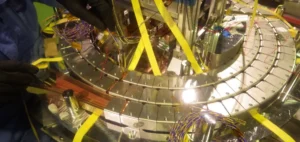

In October, the magnet cold-test cryostat equipment, the result of a collaboration between Shanghai Electric Nuclear Power Group and the Institute of Plasma Physics, Chinese Academy of Sciences (ASIPP), was shipped from China to the Port of Marseille. It was then transported 70 kilometres at walking speed to the ITER project site, which brings together more than 30 countries, including China, the United States, South Korea, and the European Union.

The delivered component is a critical part of the experimental fusion reactor infrastructure. Despite strict logistical constraints on height, width, and weight imposed by the site, assembly was completed in 11 months. The joint team successfully carried out precision welding operations, primary vacuum tests, and helium leak detection in a large-scale chamber, achieving a vacuum level of 10⁻⁴ mbar.

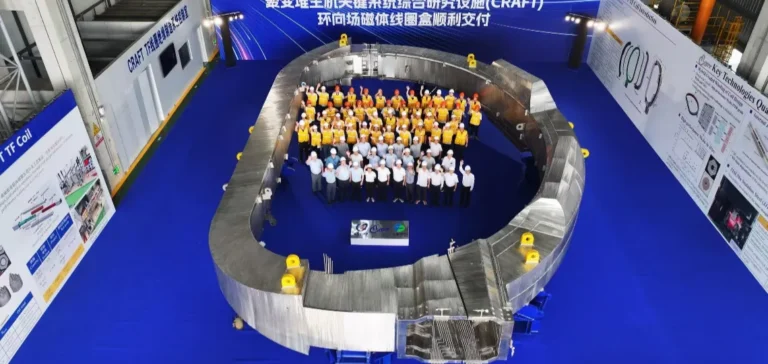

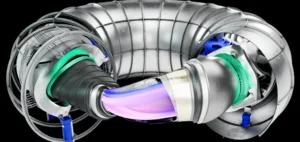

CRAFT project receives a 400-tonne coil case

At the same time, the largest toroidal field coil case ever built was delivered to the Comprehensive Research Facility for Fusion Technology (CRAFT) in Hefei. Constructed from austenitic stainless steel, it stands 21 metres high and 12 metres wide, with a weight of approximately 400 tonnes. The component is over 1.2 times larger and nearly twice as heavy as its ITER counterpart.

Shanghai Electric stated that the delivery sets a new standard for industrial-scale fusion component manufacturing. The company is also involved in other experimental projects such as EAST, BEST, and HL‑1, reinforcing its presence in high-temperature research devices.

Two decades of high-precision nuclear engineering

At the International Atomic Energy Agency (IAEA) World Fusion Energy Group ministerial meeting and the 30th Fusion Energy Conference held in Chengdu, Shanghai Electric presented two decades of advancements in fusion systems manufacturing. Company executives showcased complete system solutions, which generated strong interest from attending delegations.

The group reported mastering several complex technical processes, including hydrogen-boron fusion, high-frequency laser welding, and the production of materials resistant to extreme temperatures. These innovations, according to the company, have enhanced the reliability of experimental equipment while contributing to the international effort to develop controllable fusion energy.