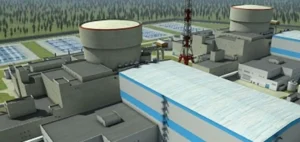

The inner dome of the Haiyang 4 reactor, located in Shandong province, has been precisely installed, marking a decisive technical advance for this nuclear project. The operation involved lifting and placing a steel structure weighing 658 tonnes, measuring about 40 metres in diameter and 11 metres in height. This component represents the final section of the reactor containment system and plays a key role in operational safety.

A key milestone for the technical phase

The containment vessel of the CAP1000 model, China’s version of the AP1000 reactor designed by Westinghouse, is composed of six modules, with this dome forming the upper part. Its installation took three hours and twenty-two minutes, requiring heavy lifting equipment. The State Power Investment Corporation (SPIC), which oversees the project, stated that this stage marks the transition from civil engineering works to the installation of technical components of the nuclear island.

The next step will be the installation of the external dome made of reinforced concrete and steel, which will cover the inner structure. This milestone will prepare future scheduled maintenance works and facilitate safety inspections planned in the construction cycle.

An approach focused on efficiency and maintenance

The project highlights modular construction methods, with CNNC Equipment Corporation prefabricating elements before assembly on site. This process not only optimises timelines but also facilitates future maintenance by standardising parts and reducing intervention complexity.

Haiyang 4 is part of a plan approved in 2022 by China’s State Council, which also includes the Haiyang 3 reactor. The first safety concrete pour for Haiyang 3 was carried out in July 2022, and construction of Haiyang 4 began in April 2024. Both units are scheduled to enter service in 2027, following an overall construction period of 56 months.

An expanding nuclear site

Haiyang already hosts two operational AP1000 reactors. The addition of two new CAP1000 units will strengthen the site’s production capacity and require strict organisation of maintenance operations to ensure long-term performance.

SPIC stated that the integration of the industrial prefabrication concept by CNNC Equipment Corporation not only saves time but also anticipates maintenance operations, with components designed to simplify regular inspections and interventions.