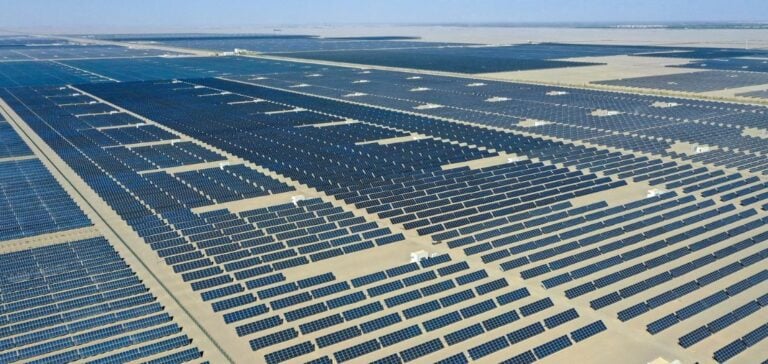

The global solar industry is on course to install 592 gigawatts (GW) of new capacity in 2024, a 33% increase on 2023, according to the latest forecasts from BloombergNEF.

This growth is largely fuelled by falling prices for photovoltaic modules, boosting demand in emerging markets such as Pakistan, Saudi Arabia and India.

However, this situation is also putting intense pressure on solar panel manufacturers, faced with increased competition and reduced margins.

The continuing fall in module prices, currently at $0.096/W (€0.087), is forcing manufacturers to reassess their market strategies.

Cost reductions are becoming a priority in the face of oversupply outstripping demand in several regions.

Japan and South Africa, for example, are seeing a decline in new installations, reflecting tougher market conditions despite global expansion.

Reducing Polysilicon Production and Impact on Profitability

Against this backdrop of overproduction, BloombergNEF adjusts its forecast for polysilicon production in 2024 to 1.96 million metric tons, down from the 2.2 million tons initially forecast.

This decision is the result of manufacturers adjusting their production capacity in response to low polysilicon prices, currently at $4.9/kg (€4.4).

At this price level, the majority of producers are operating below their production costs, jeopardizing the economic viability of some of them.

Players in the sector are adapting their operations, with some cutting back on labor, deferring payments to suppliers or reducing salaries to manage these new financial constraints.

This situation stems from systemic overcapacity throughout the supply chain, from polysilicon production to finished modules.

The BloombergNEF report anticipates that this period of tension could lead to market consolidation, with weaker companies likely to disappear or consolidate.

Manufacturers’ adjustment strategies and the future of the market

In this competitive climate, solar module manufacturers are implementing diversified strategies to maintain their operations.

Improved production processes, the adoption of new technologies such as TOPCon (tunnel oxide passivated contact), and rigorous inventory management are common measures adopted.

BloombergNEF forecasts that module prices based on this technology could fall below $0.10/W (€0.09) by the end of the year, making it more attractive for large-scale projects.

The report also points out that future growth depends on improving efficiency and reducing costs throughout the supply chain.

With a forecast of 996 GW of new installations by 2035, the solar market continues to present significant opportunities.

However, only those players capable of adapting quickly to price fluctuations and demand dynamics will be able to capitalize on these opportunities.

Supply Chain Impacts and Regional Perspectives

Pressure on the solar supply chain is also manifesting itself in capacity reductions and production adjustments.

Manufacturers must navigate between the need to maintain profitable operations and competitiveness in the face of falling module prices.

Tensions in the polysilicon market add another layer of complexity, with manufacturers forced to manage costs while avoiding significant losses.

Regional dynamics vary considerably.

While markets such as Pakistan and India are experiencing notable growth due to lower installation costs and supportive policies, others, such as Japan and South Africa, face structural and economic obstacles limiting new installations.

These regional disparities illustrate the need for companies to develop specific market strategies to maximize opportunities and minimize risks.