Belgian company John Cockerill and French group Axens have unveiled a new torrefaction technology called NesaBTF™, designed to transform lignocellulosic residues at scale into standardised feedstock for alternative fuel production. The technology builds on John Cockerill’s Multiple Hearth Furnaces (MHF) and Axens’ operational expertise in processing complex feedstocks.

An industrial solution for the BioTfueL chain

NesaBTF™ is part of the BioTfueL® process, a technological chain dedicated to converting biomass into synthetic fuels. Thanks to its modular design, the solution ensures consistent treatment of solid biomass and reduces logistics costs related to raw material transport. It aims to secure and standardise the supply of biorefineries, a critical challenge for scaling up Sustainable Aviation Fuel (SAF) production.

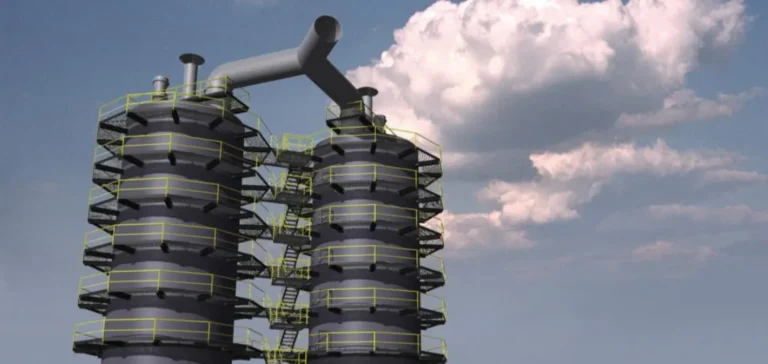

The industrial setup of NesaBTF™ is based on the integration of multiple MHF units, with over 150 references already in operation globally. The system lowers moisture content, increases energy density, and stabilises the physicochemical properties of the biomass—key factors for thermochemical conversion chains.

Towards industrialisation of low-carbon aviation fuels

Axens, a subsidiary of the French Institute of Petroleum for New Energies (IFPEN), has over 3,000 industrial references in refining, petrochemicals and alternative fuel production technologies. Its partnership with John Cockerill aims to deliver a turnkey technological offering for project developers entering the SAF market.

The flexibility of NesaBTF™ allows adaptation to various types of biomass and paves the way for cost reductions in feedstock sourcing for future commercial units. This approach could enhance the competitiveness of the European low-carbon fuel sector in relation to North American and Asian markets already under development.

The technology is designed to meet the needs of emerging markets where feedstock availability is heterogeneous, and where upstream process reliability is a key factor in project bankability.