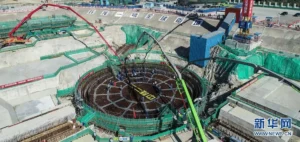

Global Nuclear Fuel, an industrial joint venture formed by GE Vernova and Hitachi, announced the commercial launch of its next-generation nuclear fuel, GNF4. The company confirmed that the first lead test assemblies will be installed in boiling water reactors in 2026, before full reload quantities are deployed from 2030.

A fuel designed to improve performance

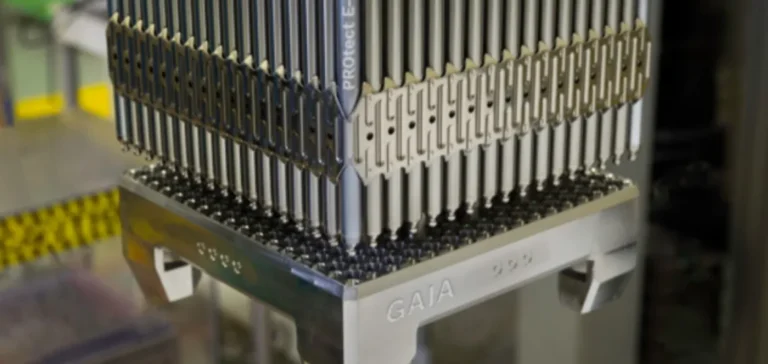

GNF4 builds on the GNF3 fuel, introduced in 2015, and incorporates two key components licensed by the United States Nuclear Regulatory Commission (NRC): Ziron cladding and aluminosilicate-doped uranium dioxide pellets. According to the manufacturer, these materials have been developed to enhance operational reliability and corrosion resistance, two essential criteria for nuclear operators facing increasing demands for performance and safety.

Ziron cladding represents an improvement over Zircaloy 2, which has been used in more than 175,000 Global Nuclear Fuel assemblies worldwide. The aluminosilicate-doped pellet provides additional thermal and mechanical stability, aiming to optimise energy yield per megawatt hour produced.

Industrial operations based in the United States

The GNF4 fuel is currently being manufactured at the Global Nuclear Fuel production facility in Wilmington, USA. This site plays a central role in the GNF4 delivery programme, ensuring a gradual production ramp-up towards full commercialisation by 2030.

Craig Ranson, Chief Executive Officer of Installed Base at GE Vernova Hitachi Nuclear Energy, stated that GNF4 is “engineered to provide plant operators with lower fuel costs per megawatt hour through increased performance and reliability.”