Global Bioenergies has begun producing isobutene at its pilot plant in Champagne. This molecule does not occur naturally, and is produced from sugars derived from beet residues, wood chips or downgraded cereals. This process reduces CO2 emissions by two-thirds.

The isobutene production process

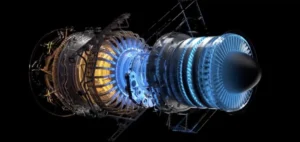

Global Bioenergies CEO Marc Delcourt explains that isobutene is produced by feeding sugars to bacteria reprogrammed to produce the molecule. “You can do all sorts of things with isobutene,” he adds. When the molecules are joined in pairs, they produce isooctane, which is used in road vehicles. When attached three by three, they give isododecane, which is the basis for aviation kerosene formulation.

Global Bioenergies’ ambition

Founded in 2008, Global Bioenergies initially set out to produce sustainable road fuels. However, the fall in oil prices led to the abandonment of this ambition. Today, the company is concentrating on the production of sustainable aviation fuels (SAF), but the necessary investment of 150 million euros is currently out of reach. To reach critical mass, the start-up is focusing on isobutene production for the cosmetics industry. Industry giant L’Oréal now owns 13.5% of the company.

Cosmetics production

Global Bioenergies produces isobutene, purifies it by removing its CO2 and packages it in gaseous form. This gas is then transformed into isododecane, which is sold to the cosmetics industry. The start-up has also created its own lipstick and mascara brand, Last. Its Pomacle plant has a production capacity of 15 to 20 tonnes a year, and is the first step on the road to the commercial market. The next objective is to open a new plant in 2025 to produce 2,000 tonnes a year, and to finance a site dedicated to sustainable aviation fuels by 2028.

The airline industry is under pressure to reduce its carbon footprint, and sustainable aviation fuels are seen as the key decarbonization lever for decades to come. Global Bioenergies therefore has an important role to play in this transition to more sustainable aviation by producing isobutene from renewable sources.