CVE Biogaz, a subsidiary of Compagnie des Énergies Renouvelables (CVE), has inaugurated its first methanisation unit in the Occitanie region. Located in the Tarn department, the facility is designed to locally convert a wide range of biowaste into biomethane. The total investment amounts to €19.7mn ($20.8mn), of which €1mn ($1.05mn) was provided by the Occitanie region under the European FEDER FESE + 2021-2027 programme.

A processing capacity focused on regional biowaste

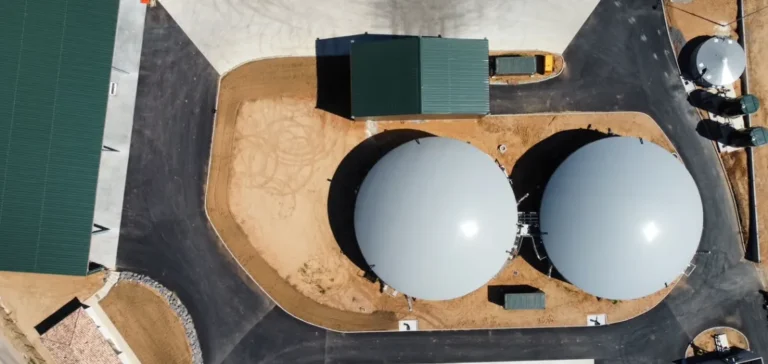

The unit, installed on a site operated by Trifyl, the departmental waste management syndicate, will process up to 21,500 tonnes of organic matter annually. Around 60% of the input will come from the agri-food industry, 22% from liquid biowaste sourced from the food service and retail sectors, and 18% from agricultural waste. The plant aims to maintain a local footprint by collecting waste within an average one-hour radius.

The facility will produce 320 Nm³ CH₄/h, or 32 GWh annually, injected into the local network operated by Teréga. This output is equivalent to the annual energy consumption of 2,600 households or 117 buses running on BioGNV, according to technical data provided.

An integrated model for local valorisation

CVE Biogaz has structured its supply chain around two sites: the CVE Tarn methanisation unit and the Sud Waste Proxi deconditioning centre in Saint-Lys. The latter, operational since June, can process 18,000 tonnes of packaged biowaste per year. Separating packaging upstream reduces transport distances and ensures optimal input quality for the CVE Tarn site.

The digestate from the methanisation process will be spread over 1,970 hectares of farmland operated by 47 partner farmers. This return to soil completes the valorisation cycle with local management of organic fertilisers.

A growing sector led by an integrated operator

CVE Biogaz currently operates 10 methanisation units, with 5 under construction and around 20 in development. The company positions itself as the only independent operator in France managing the entire value chain—from collection and deconditioning to biomethane production and soil return.

The company processed 345,000 tonnes of organic waste in 2024. All its projects are based on a model of proximity and medium-scale units, in cooperation with local authorities, economic stakeholders, and farmers.