Brazil is accelerating the development of its rare earth sector with 27 projects identified by the National Mining Agency (Agência Nacional de Mineração), distributed among 17 companies operating in seven states. These initiatives aim to tap into the world’s second-largest rare earth reserve and build a supply chain independent of flows dominated by China.

Australian companies at the forefront

In Poços de Caldas, in the state of Minas Gerais, Viridis Mining and Minerals and Meteoric Resources hold exploration rights for ionic clay deposits. Viridis plans an investment of $280 million to fund its operations, notably through long-term offtake agreements. The company is in talks with development banks in Europe and Japan to secure commitments for building a selective separation refinery in partnership with Ionic Rare Earths.

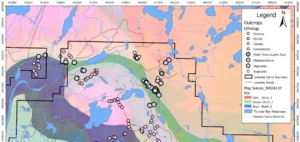

In Bahia state, in the city of Jequié, Brazilian Rare Earths and Equinox Research are focusing drilling efforts on hard rock and ionic clay formations. Tiago Abreu, chief development officer at Brazilian Rare Earths, stated that ore grades reach up to 30% rare earth oxides. He estimates that Brazil could hold 21 million metric tons in reserves, strengthening its strategic supply potential.

Energy security and industrial policy

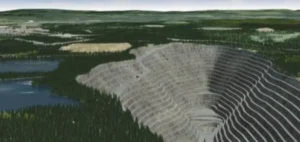

The concentration of global production in China presents an increasing risk for consuming industries. Murilo Nagato, country manager at Aclara Resources, said geopolitical tensions are pushing companies to diversify partnerships to limit exposure to the Chinese market. In 2024, Serra Verde became the first company to launch commercial rare earth mining operations in Brazil, located in Minaçu, in the state of Goiás.

In response to growing demand, the National Bank for Economic and Social Development (Banco Nacional de Desenvolvimento Econômico e Social), in partnership with the Financing Agency for Studies and Projects (Financiadora de Estudos e Projetos), launched a public call for proposals. The programme includes a funding envelope of BRL5bn ($893mn) to support investments in strategic mineral value chains. An additional BRL1bn ($178mn) fund will target small and medium-sized enterprises in the sector.

Operational costs and market segmentation

Rare earths include 17 chemical elements essential to the manufacturing of magnets, screens, and electronic components. Neodymium and praseodymium are used to produce supermagnets for electric motors and wind turbines, while dysprosium, terbium, and europium enhance the thermal and visual performance of various devices. However, their chemical separation remains complex and requires specialised technologies.

Marcelo de Carvalho, country manager at Meteoric Resources, stated that operational costs for Brazilian projects are close to those in China, allowing for potential long-term competitiveness. He emphasised the importance of developing a traceable supply chain to meet the expectations of markets concerned with the origin of raw materials.