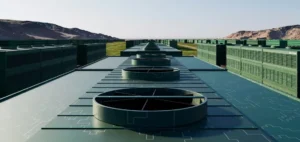

The construction of the world’s first industrial-scale carbon capture plant in a cement facility marks a significant milestone in the fight against greenhouse gas emissions. SLB Capturi, in partnership with Heidelberg Materials, has completed the facility in Brevik, Norway, which is now ready for testing and commissioning phases.

This project, which represents an unprecedented advancement in the cement sector, is designed to capture up to 400,000 metric tons of CO2 annually, contributing to the production of carbon-neutral cement without compromising its essential properties. The facility incorporates capture, compression, heat integration, intermediate storage, and loading systems, showcasing cutting-edge engineering and fruitful collaborations with actors like Aker Solutions.

A Model for the Cement Industry

Cement, due to its manufacturing process, is one of the most CO2-intensive materials. The Brevik CCS (Carbon Capture and Storage) initiative illustrates the vital role this technology plays in achieving global climate targets. This project, which is part of the Longship CCS initiative, also serves as a concrete example of how the industry can innovate to tackle climate challenges.

According to Egil Fagerland, CEO of SLB Capturi, “Reaching this milestone reflects the power of collaboration and the collective determination to create a positive climate impact.” He also emphasized that the lessons learned from this groundbreaking project will serve as a benchmark for similar initiatives worldwide.

Environmental and Economic Benefits

The Brevik CCS project is part of an ambitious effort to establish the first complete value chain for CO2 capture, transport, and storage in Europe. In addition to reducing direct emissions, it paves the way for new economic solutions for sectors reliant on hard-to-decarbonize industrial processes.

Giv Brantenberg, General Manager for Northern Europe at Heidelberg Materials, stated, “This achievement exemplifies our commitment to innovation and collaboration in addressing the urgent challenges of climate change. We are proud of the efforts of our teams and partners.”

As the facility begins its commissioning phase, optimistic prospects emerge for operations to start as early as 2025. This milestone could transform how heavy industries envision their role in the energy transition.