Plug Power, world leader in hydrogen solutions, has signed a Basic Engineering and Design Package (BEDP) with Allied Green Ammonia (AGA) for a 3 GW electrolysis plant in Australia. This project is essential for the production of 2,700 tonnes per day (TPD) of green ammonia, scheduled for the fourth quarter of 2025.

Development and Environmental Impact

The BEDP contract enables AGA to finalize the design of its green ammonia project by integratingPlug’s electrolyzers. Alfred Benedict, founder and managing director of AGA, emphasized the importance of this agreement, saying it was a “significant step in the development of one of the world’s leading green ammonia production facilities”. The production of green hydrogen by electrolysis replaces traditional steam methane reforming techniques, thus reducing CO2 emissions.

Technology and benefits

Plug Power’s proton exchange membrane (PEM) electrolyzers are pressurized to 40bar, reducing the need for downstream compression. What’s more, the oxygen extracted from electrolyzedhydrogen can improve the efficiency of industrial power plants thanks to its ability to burn at high temperatures. Plug’s modular units are fully factory-assembled and easily transportable, facilitating deployment in remote areas.

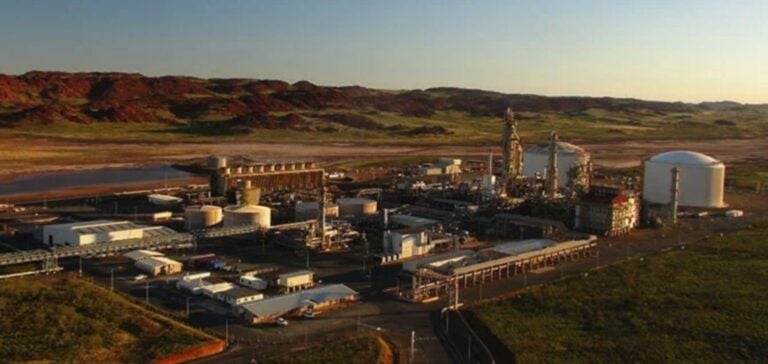

Strategic position and outlook

The facility’s location on Australia’s Gove Peninsula is strategic, given the abundant renewable energy resources and robust local energy infrastructure. This geographical position favors commercial partnerships with Asia, guaranteeing a reliable and secure supply of green ammonia for AGA’s customers. Andy Marsh, CEO of Plug Power, said, “Moving to the BEDP phase of this major ammonia green hydrogen project is a sign of maturity in the development process.” In this way, the project aims to contribute to decarbonization objectives.