Orano recently introduced the TN Eagle, a new-generation packaging model. This development marks a significant step forward in the safety and efficiency of spent nuclear fuel transportation. Approved by France’s Nuclear Safety Authority (ASN) in 2020, the TN Eagle meets the latest International Atomic Energy Agency (IAEA) standards. In fact, this success is based on a series of rigorous tests, attesting to its robustness in the face of extreme transport conditions.

The TN Eagle’s innovative design features a modular structure to meet the diverse needs of nuclear power plant operators. Frédéric de Agostini, Orano’s Executive Vice President for Nuclear Packaging & Services, points out that this design considerably reduces the number of transport packaging components by a factor of ten, while cutting manufacturing times and boosting safety and competitiveness.

Adaptation and Approval in the United States

Despite its approval in France, the TN Eagle model had to be adapted to meet specific US requirements for spent fuel storage. However, approval from the Nuclear Regulatory Commission (NRC) in the United States is a key milestone for Orano, paving the way for significant expansion in the transportation of used nuclear fuel in the US market.

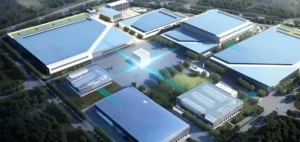

Construction and future of TN Eagle 4.0

The development of the TN Eagle is part of a major project involving the construction of a new factory in Cherbourg, France. However, launched in February 2023, the project is supported by the France Relance investment fund. Commissioning of the TN Eagle 4.0 plant is scheduled for 2024. The facility is designed to reinforce Orano’s position as a leader in the nuclear transport sector, while contributing to the local and national economy.

The TN Eagle represents a major technological breakthrough in the nuclear transport sector, offering a safer, more efficient and more competitive solution. This development illustrates Orano’s commitment to innovation and nuclear safety, while responding to the changing needs of the global market.