Nel ASA (Nel) is now focusing exclusively on the development and supply of world-class electrolyzers to produce renewable hydrogen, following the demerger of its hydrogen refueling division, now listed as Cavendish Hydrogen.

Hundreds of years of expertise at the service of innovation

Nel ASA has been developing electrolyzers for almost a century, and has installed thousands of systems worldwide. This unrivalled experience is now entirely dedicated to creating the most reliable and energy-efficient electrolyzers. The demerger of the supply division marks a strategic turning point, allowing Nel to concentrate all its resources on this ambition. With around 450 employees based in Norway and the United States, Nel will leverage its know-how to offer cutting-edge electrolysis solutions that meet the growing needs of the global renewable hydrogen market.

Accelerated development of new-generation electrolyzers

Nel is investing heavily in next-generation technologies, improving its current PEM (Proton Exchange Membrane) and atmospheric alkaline electrolyzers, while developing new-generation pressurized alkaline and PEM electrolyzers. In collaboration with General Motors, Nel is making rapid progress in the development of PEM electrolyzers. In addition, the revolutionary redesign of the pressurized alkaline concept has reached the prototype stage. These advances are supported by funding from the US Department of Energy to develop AEM (Anion Exchange Membrane) electrolyser technology.

Strategic partnerships with industry leaders

Recently, Nel signed a technology licensing agreement with Reliance Industries, India’s largest private company. This agreement gives Nel access to a fast-growing market and enables it to meet worldwide demand for Reliance electrolyzers. In addition, Nel has partnered with several engineering, procurement and construction (EPC) companies to offer 100 MW turnkey building blocks.

Annual production capacity in gigawatts

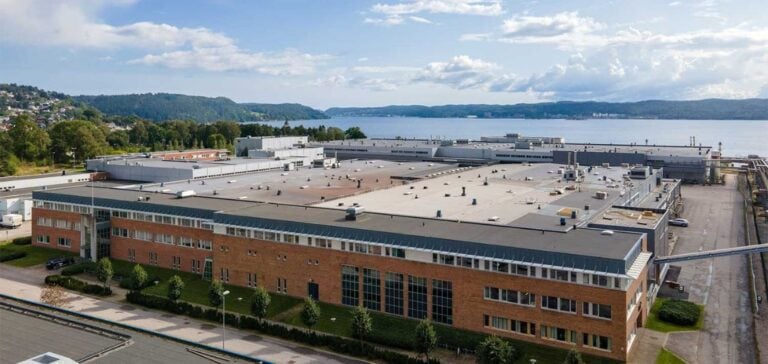

Over the past year, Nel has taken significant steps to prepare the company for further growth. Annual production capacity at the fully automated electrode manufacturing plant in Herøya, Norway, has doubled to 1 GW. In the United States, Nel is also increasing its annual production capacity to 500 MW at its PEM manufacturing plant in Wallingford, Connecticut. These fully-automated installations optimize production processes and enable us to internalize several steps previously outsourced. The company has also secured around US$170 million in support from the US Department of Energy and the State of Michigan for its planned gigafactory in Detroit, where the next-generation PEM and pressurized alkaline electrolyzers will be manufactured. Nel’s first-quarter 2024 results show that the company is on track to achieve sustainable profitability, with the alkaline division achieving positive EBITDA. “Our revenues and EBITDA continue to improve, demonstrating that our business model is working on a large scale,” said Nel CEO Håkon Volldal at the results presentation.