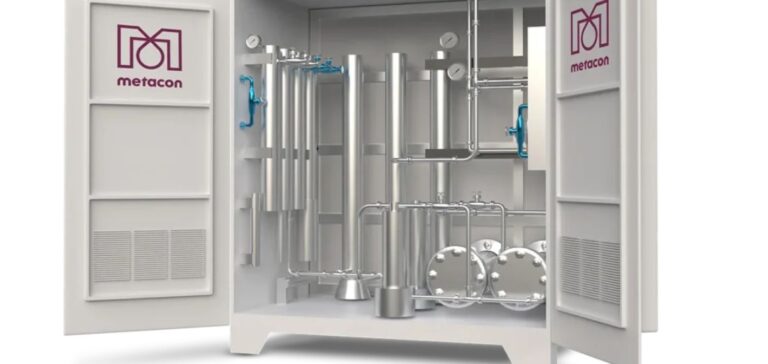

Metacon AB, a Swedish company specialising in hydrogen production technology, has secured a contract to supply a 20 MW high-pressure electrolyser unit to Motor Oil Hellas. The contract, valued at €10.6 million, is part of the expansion of Motor Oil’s hydrogen production site in Corinth, Greece. This electrolyser unit will complement an earlier 30 MW project by Metacon, raising the total plant capacity to 50 MW.

The assembly of the new unit will take place at Metacon’s factory in Patras, Greece, and the installation on-site in Corinth will be supervised by Metacon and its Chinese partner, PERIC. This high-pressure electrolyser unit will make the Corinth plant one of the largest hydrogen production facilities in Europe based on electrolysis.

Hydrogen production is a central element in Europe’s energy transition, and this agreement marks a strategic development for Metacon, aiming to position itself as a key supplier in the sector. The contract aligns with Metacon’s industrial strategy to strengthen its presence in the European clean hydrogen market.

strategic expansion in greece

Motor Oil’s site in Corinth is one of the most modern industrial complexes in Europe, and this addition will strengthen its position in large-scale hydrogen production. Metacon, in collaboration with PERIC, its Chinese manufacturing partner, aims to make hydrogen more competitive in the European industrial market. Christer Wikner, CEO of Metacon, stated that this contract represents an important step towards achieving the company’s financial goals for the year.

Large-scale hydrogen production facilities are increasingly seen as a cornerstone for achieving European climate targets. The Metacon and Motor Oil project will help meet the growing demand for hydrogen in industrial sectors, at a time when the EU seeks to reduce its CO2 emissions.

long-term collaboration for clean hydrogen solutions

The collaboration with PERIC is crucial for Metacon’s competitiveness in large-scale electrolysis. Through this partnership, Metacon is able to offer hydrogen production systems that are both efficient and cost-effective. This cooperation will help reduce production costs, while ensuring proven technology to meet the needs of the industrial market.