The International Atomic Energy Agency (IAEA — French: Agence internationale de l’énergie atomique) established that Iran’s stock of uranium enriched to 60% reached 440.9 kg in the form of uranium hexafluoride (UF6). According to the agency’s methodological yardstick, that quantity, if further enriched, represents a potential of roughly ten nuclear devices. The agency notes the material is in gaseous form, usable in centrifuge cascades to continue enrichment. Since the strikes targeting enrichment capabilities, the IAEA reports it lacks verified information on the exact status and location of the highly enriched stock.

Quantity, enrichment and conversion potential

Immediately prior to the military operations, the 440.9 kg of UF6 at 60% represented an increase compared with previous assessments. The 60% threshold lies close to the so-called weapons-grade level, generally associated with 90% uranium-235, and shortens the technical time required for final conversion. Effective yield, however, depends on industrial parameters including cascade configuration, separation factor and the operational availability of units. The reference to “ten devices” reflects an internal calculation yardstick used by the IAEA and does not imply specific designs or account for process losses.

The UF6 chemical form governs the entire isotope-separation chain and the handling constraints that accompany it. Material flow requires reliable feed, compression and vacuum systems to maintain centrifuge stability. Electrical continuity, rotor quality and line cleanliness directly influence achievable enrichment rates. Any prolonged interruption or infrastructure damage translates into efficiency losses and longer restoration work.

Facilities and reported damage

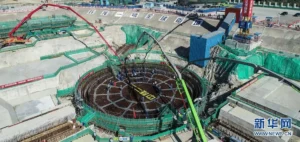

Strikes targeted sites linked to enrichment, including Natanz, Fordow and a complex in the Isfahan region. The Israel Defense Forces (IDF — French: Forces de défense d’Israël) stated that Iran possessed sufficient fissile material to assemble several devices on a short timeline and referenced a ramp-up in missile production. A communication from the Israel Atomic Energy Commission (IAEC — French: Commission israélienne de l’énergie atomique), shared by the U.S. executive, asserted that Fordow had been rendered inoperable. Commercial satellite imagery showed truck movements and earth-moving activity near underground entrances, with no independent IAEA access to characterize the extent of the damage.

The IAEA indicates that access modalities for affected installations remain under discussion with the Iranian authorities. Director General Rafael Grossi signaled that talks could not continue indefinitely and called for a prompt agreement on inspections and verification. The agency has not confirmed any transfer of stock or relocation of production units due to the absence of on-site inspections since the strikes. The precise status of centrifuge cascades at Fordow and Natanz therefore remains unverified by the monitoring body at this stage.

Operational parameters and watch points

Industrial operators typically assess three variables to estimate an enrichment program’s trajectory after an incident: the integrity of underground halls, the availability of reserve equipment and the capacity to restore power and process utilities. A combination of structural damage and access constraints can prolong restart timelines beyond planned maintenance windows. UF6 flows require a stable logistical chain from production through containment, making any disruption immediately visible in material balance sheets. The lack of IAEA access sustains uncertainty over volumes that are actually operational and over the timing of any resumption.

For stakeholders exposed to geopolitical risk, developments in inspection access, the real condition of enrichment capacity and the management of highly enriched stocks form the three decisive short-term indicators. Public statements by the parties provide reference points, but only field verification will refine the inventory and the configuration of cascades. Visibility on material availability and plant integrity will shape risk expectations tied to the region. The situation is therefore monitored through control channels and imagery pending verified parameters.