A dedicated steam supply unit has started at Tianwan Nuclear Power Station (TNPS) to feed large-scale industrial processes. Heqi No. 1 targets annual production of 4.8 mn tonnes of so-called zero-carbon steam for the Lianyungang petrochemical complex. This capacity relies on heat extraction from the reactor and a dedicated chain of equipment for thermal conversion. The initiative is presented as the first in the world to reach this volume for industrial steam produced using nuclear energy.

Capacity and industrial integration

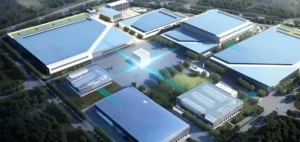

The site lines up eight nuclear units, six of which are operational, for an installed capacity above 6.6 mn kilowatts. The units in service supply about 158 mn kilowatt-hours (kWh) per day to the East China Power Grid. The Heqi No. 1 steam spur is connected to the petrochemical hub to ensure continuous supply for heating, drying and equipment drive. The technical scheme provides a dedicated control interface to adjust flows according to the industrial site’s demand.

Industrial steam requires temperatures above 260 °C, achieved through multi-stage heat exchange. The system includes preheaters, steam generators and superheaters coordinated by pumping and automation systems. The central conversion unit extracts reactor steam and transfers it through partitioned heat exchange without fluid contact. “The operation is similar to a self-heating hotpot,” said Li Ruigang, deputy director of the Operation Division No. 2, Jiangsu Nuclear Power Corporation.

Operational tuning and testing

Shifting from exclusively power generation to industrial heat supply requires a dynamic balance between production and consumption. The engineering team conducted reverse engineering of hundreds of reactor–turbine control parameters over nearly seven months. In March 2024, a “Reactor–Turbine Heat Matching” test validated synchronisation of extracted heat with steam demand. This configuration targets stability of steam characteristics and service consistency.

The programme spanned six years from design to construction, with successive patent filings. The work resulted in thirty-seven technological innovation patents covering heat–power integration, exchange trains and control systems. Application extensions are being studied in industry, medicine, agriculture and security along validated technical lines. It is the first project to provide industrial steam at this scale based on nuclear energy.