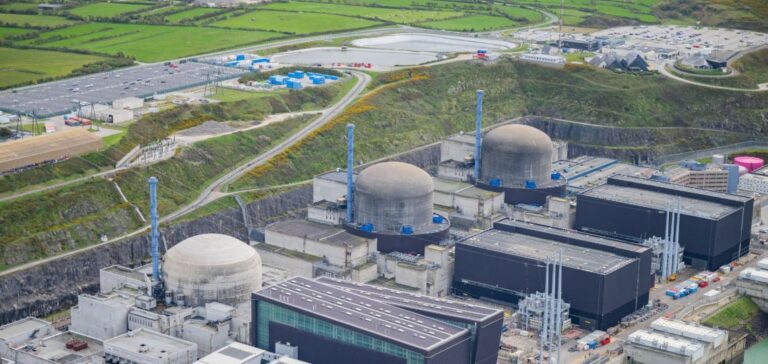

Since February 15, the Flamanville EPR nuclear reactor has been undergoing an unscheduled shutdown for a series of technical interventions. Initially expected to last for a shorter period, this shutdown will now extend until March 30, according to the operator. These operations are part of the adjustments required for the reactor’s gradual commissioning.

When it was connected to the power grid in December, the operator indicated that the reactor’s power increase would follow a progressive process, potentially requiring multiple scheduled maintenance shutdowns. A company executive noted that such adjustments are common for new installations, describing them as part of a technical break-in phase. These events, referred to as technical contingencies, do not call into question the installation’s design.

Successive technical interventions

The first shutdown, which took place on February 15, was dedicated to an intervention on a cooling circuit using seawater. This system, intended to be activated only in exceptional situations, showed a decline in performance that required correction.

On February 22, the shutdown was extended to allow for work on a temperature sensor in the primary circuit, which is responsible for transferring heat from the reactor core to the steam generators.

Optimisation of the turbo-alternator group

Another extension was decided on February 28 to carry out adjustments on the turbo-alternator group. This key component, consisting of a turbine and an alternator, ensures the conversion of thermal energy into electricity. The intervention focuses on two bearings, crucial elements for guiding and supporting the device’s rotors.

At the same time, additional maintenance work is underway on a second temperature sensor in the primary circuit. These adjustments follow two scheduled production shutdowns that took place after the reactor was connected to the power grid.

Power increase target maintained

The operator still expects to reach 100% power by the summer, despite these interventions. Although initially unforeseen, these technical adjustments are considered part of the reactor’s optimisation process before full-scale operation.