Air Products, a world leader in liquefied natural gas (LNG) technology and equipment, announced the signing of an agreement with Technip Energies to provide its proprietary LNG liquefaction technology and equipment for the Xi’An Emergency Reserve and Advanced Regulation Project with Shaanxi LNG Reserves & Logistics Company Ltd in Shaanxi Province, China.

Technology essential to the project

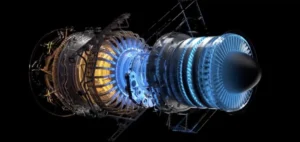

Air Products’ technology will be essential for the liquefaction train producing 800,000 tons per year of LNG when the plant is operational. The agreement includes the supply of AP-SMR™ LNG liquefaction technology, as well as the design, engineering and fabrication of the main cryogenic coil heat exchanger for the liquefaction section of the plant. Air Products will also provide technical advisory services for installation, commissioning and performance testing during start-up.

It will be the world’s largest liquefaction unit using a single mixed refrigerant compressor driven by an electric motor, enabling low-carbon LNG production to meet the growing demand for clean energy. The LNG produced will be distributed to the Chinese market for use in residential and industrial applications.

Equipment built in Florida

The Xi’An Emergency Standby and Advanced Regulation project is Air Products’ fourth medium-sized liquefaction train placement in China, the most recent being the Yangling LNG project, which also uses Air Products’ AP-SMR LNG liquefaction technology and coil heat exchanger. The LNG equipment will be built at Air Products’ world-class facility in Port Manatee, Florida, which opened in January 2014 and completed a 60 percent expansion in October 2019 to meet the needs of the evolving LNG industry.

In October 2018, a new LNG equipment testing facility opened, allowing Air Products to continually improve the reliability and performance of its LNG equipment and design new equipment. Air Products’ proprietary LNG process technology and equipment are critical to meeting the world’s growing energy needs and demand for clean energy, and allow valuable natural gas to be cryogenically liquefied for industrial and commercial use.