Baker Hughes announced it has received full notice to proceed from Technip Energies for the supply of liquefaction equipment for the Commonwealth LNG gas project, currently under development in Cameron, Louisiana. The project is designed for an annual output capacity of 9.5 million tonnes of liquefied natural gas (LNG), with deliveries intended for the global market.

A major order for a strategic project

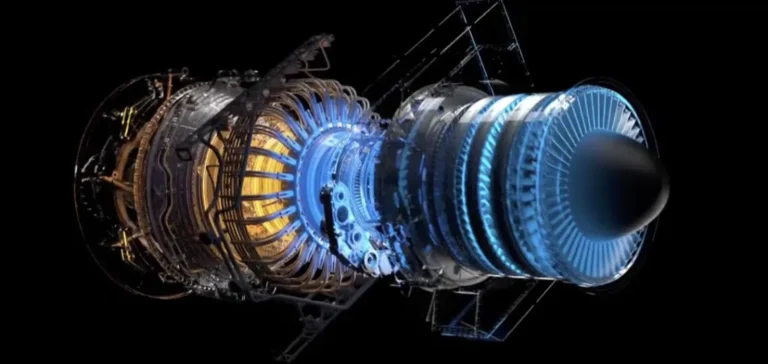

The order includes six mixed refrigerant turbomachinery trains, each consisting of one LM9000 gas turbine coupled with a centrifugal compressor. This equipment is designed to deliver superior energy efficiency, enhanced reliability and reduced carbon intensity. Baker Hughes will also provide commissioning services, critical capital spares, extended warranty and a full string test.

The partnership is part of a broader strategic agreement between Commonwealth LNG and Baker Hughes, covering advanced technology solutions, operational services and digital tools. The close collaboration between Technip Energies, the project’s main contractor, and Baker Hughes is aimed at ensuring schedule compliance and facility performance.

An industrial milestone in the project’s development

The Chief Executive Officer of Caturus, parent company of Commonwealth LNG, referred to this as a “significant capital investment”, marking a key step in the project’s progression and highlighting its role in the integrated wellhead-to-water strategy. The project’s financing structure is also underway, though no final investment decision date has been announced.

The Chief Executive Officer of Technip Energies acknowledged further progress in developing the project, emphasising the long-standing collaboration with Baker Hughes on modular infrastructures designed to meet growing LNG demand. Commonwealth LNG’s model relies on standardised modular design to speed up delivery and reduce capital expenditure.

Key technology for US export capacity

The LM9000 turbine is currently the most efficient in its class, offering 44% efficiency in ISO conditions, according to its specifications. Its compact format and extended maintenance intervals make it a preferred option for LNG installations requiring high availability. This type of equipment is becoming central to US liquefaction projects focused on optimising operational efficiency.

With this contract, Baker Hughes strengthens its position across the LNG value chain, particularly in the North American market where liquefaction projects remain active despite a complex regulatory and geopolitical environment. The company is emerging as a key supplier of next-generation equipment for large-scale energy infrastructure.