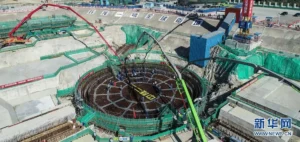

Westinghouse Electric Company congratulates CNNC Sanmen Nuclear Power Company Limited and its partners on the pouring of the first nuclear concrete for Sanmen Unit 4. This marks an important milestone in the deployment of AP1000® technology, which promises economic and planning benefits through its Nth-of-a-kind deployment and modular construction.

The pouring of the first nuclear concrete for Sanmen Unit 4 is a testament to the strength of the partnership between Westinghouse and CNNC Sanmen Nuclear Power Company Limited. This is a crucial step in the construction of the AP1000®nuclear power plant, which will provide safe, reliable and sustainable energy to the people of China.

AP1000® : the safe and economical nuclear technology of tomorrow

The AP1000® technology is at the forefront of the nuclear industry, with its modular construction and Nth-of-a-kind deployment offering significant advantages. The AP1000® design includes passive safety systems, which ensure that the plant can safely shut down and cool down without the need for external power or human intervention. This makes the AP1000® design one of the safest nuclear power plant designs in the world.

The modular construction of the AP1000® design allows the plant to be built in a controlled manufacturing environment, reducing construction time and costs. The modules are then transported to the construction site, where they are assembled, further reducing construction time and costs. This modular construction approach also allows for better quality control and improves safety, as modules are tested and inspected before leaving the factory.

Thus, the pouring of the first nuclear concrete for Sanmen Unit 4 is an important milestone in the deployment of AP1000® technology. It promises economic and planning benefits through its nth-of-a-kind deployment and modular construction. Westinghouse Electric Company congratulates CNNC Sanmen Nuclear Power Company Limited and its partners for reaching this milestone.