The Clipper Eris is a 160-meter ethylene carrier owned by the Solvang group (Solvang). Powered by heavy fuel oil (HFO, Heavy Fuel Oil), this vessel uses a fuel known for its significant emissions of sulfur and greenhouse gases (GHG). In an effort to reduce the carbon footprint of the high-sea fleet, the shipowner decided to carry out a retrofit (technical renovation) to install an advanced exhaust gas filtration system. This is an experimental approach that draws the attention of many maritime stakeholders interested in concrete decarbonization solutions.

A capture system onboard

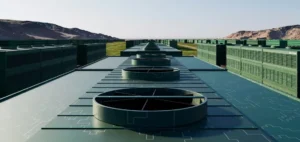

The installed device captures carbon dioxide directly in the exhaust line. Through a separation process, the CO2 is extracted and then liquefied to reduce its volume before being stored onboard. Specially equipped tanks preserve this CO2 for possible industrial reuse or later burial in geological formations. According to the engineers involved, this solution aims to reduce GHG emissions by up to 70%, while maintaining the vessel’s operational performance.

This process, known as Onboard Carbon Capture and Storage (OCCS), is still in the experimental stage within the maritime industry. Several challenges remain, including managing the heat generated during capture, the energy consumption required to operate the system, and the issue of long-term profitability. Nonetheless, the shipowner emphasized that Norwegian public funding partially supported this project, which helps offset some of the initial costs. Those involved see it as an important step toward decarbonizing a global fleet responsible for 2 to 3% of total GHG emissions.

The role of the International Maritime Organization

The International Maritime Organization (IMO) is responsible for regulating international maritime transport. It has set targets to reduce net greenhouse gas emissions, with progressive short- and medium-term goals. Shipowners are therefore encouraged to explore various pathways, whether by adapting existing vessels or designing new ones capable of operating with cleaner technologies. In this context, the OCCS solution stands out as a feasible avenue for meeting regulatory constraints on pollutant emissions.

Officials at Solvang and its partners believe that implementing an onboard CO2 capture system can be combined with other emission reduction methods, such as speed optimization or route adjustments. This approach could address the growing demand for cargo transport while taking environmental imperatives into account. According to Solvang CEO Edvin Endresen, the goal is to prove that this system can be integrated on conventional cargo ships without disrupting freight or operational safety.

Perspectives and future development

Seven Solvang vessels under construction are said to be already designed to accommodate an OCCS system. Stakeholders such as Wärtsilä Marine (WM) have joined the project by bringing their expertise in marine engine design and adaptable technological solutions. According to WM engineers, the idea is to ensure that future generations of ships can incorporate similar innovations, offering operational versatility while reducing the release of polluting gases into the atmosphere.

The commissioning of such a system demonstrates the potential for directly onboard carbon capture and storage devices. Shipyards are increasingly interested in these approaches, as they can be applied to existing fleets, not just new vessels. Stakeholders point out that a substantial reduction in emissions at the source will help the sector meet IMO requirements, while limiting dependence on alternative energies that are still not widely available in the maritime market.

However, some observers stress the need to gather more data on the actual performance of this system on a large scale. Despite the stated ambitions, its integration on other types of vessels, evolving costs, and future regulations could affect its widespread adoption. This project therefore raises questions about adaptability, financing, and environmental performance, all of which are of interest to a maritime sector in the midst of transformation.