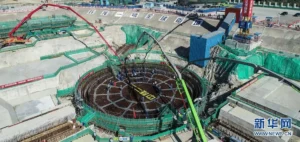

The ACP100 reactor building comprises three essential parts: the internal structure, the steel containment shell and the concrete outer protection shell. The steel containment shell is divided into four distinct parts: the lower head, the lower cylinder, the upper cylinder and the upper head. Moreover, the shape of this shell is similar to a standing capsule, housing the internal structure of the reactor building.

Ingenious assembly

The lower head of the containment vessel, which supports the steel containment shell, was assembled on site from 50 prefabricated steel plates. Indeed, this assembled component was carefully hoisted into place by crane on the plant’s concrete foundation plate on October 24, 2021. The lower section of the containment shell, measuring around 15 metres in height and weighing around 450 tonnes, was lowered into place on the lower caisson head on February 26, 2022, 46 days ahead of schedule.

Crucial steps

This success was followed by the installation of the upper cylinder of the containment shell, some 15 metres high and weighing around 720 tonnes, on July 6 last year. Finally, the upper containment head for the ACP100 was installed on November 3, marking a major milestone in construction.

Innovative Construction

Linglong One’s modular, open-roof construction method reduced building costs and saved time, thanks to the standardized design and mass production of individual modules. This efficient approach accelerated the construction process while maintaining high safety and quality standards.

Major breakthrough in Nuclear Energy

In July 2019, CNNC announced plans to build the ACP100 reactor in Changjiang, in China’s southern island province of Hainan. Likewise, the site is already home to two CNP600 PWR units in operation, and construction of two Hualong One units has begun in March and December 2021. Both units are scheduled to go into commercial operation by the end of 2026. The ACP100 reactor saw its first concrete pour on July 13, 2021, with a total planned construction period of 58 months. Work to install the equipment began in December 2022. The main internal structure of the reactor building was completed in March of this year.

An innovative modular PWR nuclear reactor

Under development since 2010, the preliminary design of the 125 MWe integrated ACP100 was completed in 2014, becoming the first SMR to pass an International Atomic Energy Agency safety review in 2016. Once completed, the Changjiang ACP100 reactor will be capable of generating 1 billion kilowatt-hours of electricity per year, meeting the energy needs of 526,000 households. It is designed for power generation, heating, steam production and seawater desalination.

Essential collaboration

The Changjiang project is the fruit of collaboration between three main companies: CNNC subsidiary China National Nuclear Power as owner and operator; the China Institute of Nuclear Energy as reactor designer; and China Nuclear Power Engineering Group as plant builder. Key players such as Shanghai Boiler Works Limited supply the reactor vessel, and CNNC subsidiaries contribute steam generators and other internal reactor components.

The completion of key stages in the construction of the ACP100 reactor marks an important milestone in nuclear power generation in China. This efficient, standardized approach promises to provide a reliable, sustainable source of energy to meet growing needs for electricity, heating, steam production and seawater desalination. The Changjiang project continues to make diligent progress, paving the way for a promising energy future.