China’s XTC and France’s Orano made official their partnership on Tuesday to manufacture battery components for electric vehicles in France, a production for which Orano expects to use 30% recycled materials in the long term, a way of partially circumventing the struggle for the supply of raw materials.

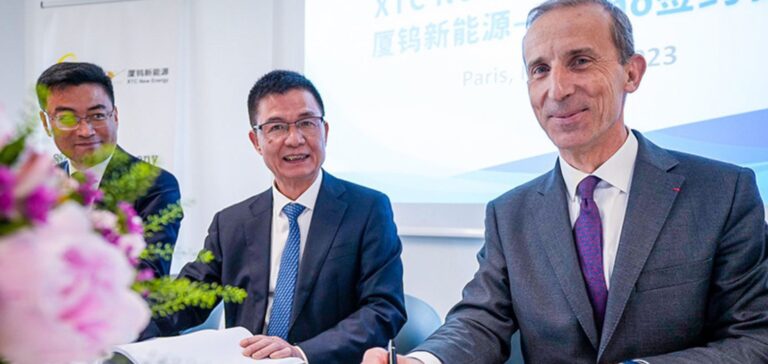

Orano, an industrial company specializing in the recovery and transformation of nuclear materials, and the XTC New Energy group, a specialist in the production of cathode materials for batteries, “have signed agreements to create two joint ventures dedicated to the production of critical materials for electric vehicle batteries,” Orano announced in a press release Tuesday. They thus confirm the announcements of Emmanuel Macron, Friday, during a trip on the theme of reindustrialization in Dunkirk, where they plan to establish two production plants on the same site, for an investment of 1.5 billion euros in total.

The recycling plant will open in 2026

More precisely, these two plants represent an investment of 1.3 billion euros, with the remainder to finance “the establishment of a battery recycling plant nearby”, a process currently at the industrial pilot stage in the Limousin region, according to Didier David, director of the battery project for Orano. “We will have the manufacture of precursors of cathode materials, the manufacture of cathode materials as such which will provide turnkey components to battery manufacturers as such and then the recycling plant, recovery of materials to extract them again and re-supply the precursor plant, “summarized Mr. David, in an interview with AFP.

Orano will rely on a process it has been working on since 2020 with Liten, a Grenoble-based laboratory of the French Atomic Energy Commission (CEA), which specializes in energy transition technologies: if it keeps to its schedule, the recycling plant will open, like the other two, in 2026 “and therefore in time to both recycle the waste from the gigafactories” installed in the region “and gradually the batteries at the end of their life,” said David. “This process must gradually increase in power. It is expected to eventually constitute up to 30% of supplies but at the beginning it is quite obvious that we will have to rely on the purchase of metals such as cobalt, nickel and lithium,” said David to AFP.

In addition to the European obligations for manufacturers to use batteries with recycled materials, “given the availability of raw materials, recycled material will become a fundamental data, what we will call a kind of urban mine so that eventually, an increasingly important part of the materials come not from mines, but from our own consumption,” added David.