The world’s first nuclear space saver has been produced thanks to a collaboration in Cumbria. It is the result of a synergy between British companies West Cumberland Engineering, Bendalls Engineering and TEAM Industrial Services. They have developed a technology called “Hybrid 1 63 Can Rack”. This nuclear space saver has been delivered to the Sellafield power plant. Via a new nuclear decommissioning site licensing company controlled by the UK Nuclear Decommissioning Authority.

This nuclear space saver offers significant savings

This new technology was expected to save England £2 billion on nuclear decommissioning costs. In addition, this installation would help reduce the time needed to remove fuel from AGR reactors.

Andrew Pringle, head of Sellafield’s AGR program, told Cumbria Crack:

“This will enable us to support ongoing AGR receipts and accelerate the bulk unloading of AGR reactors from 8 years to 3.5 years. This is good news for the taxpayer, as it will save around £2 billion on decommissioning costs.”

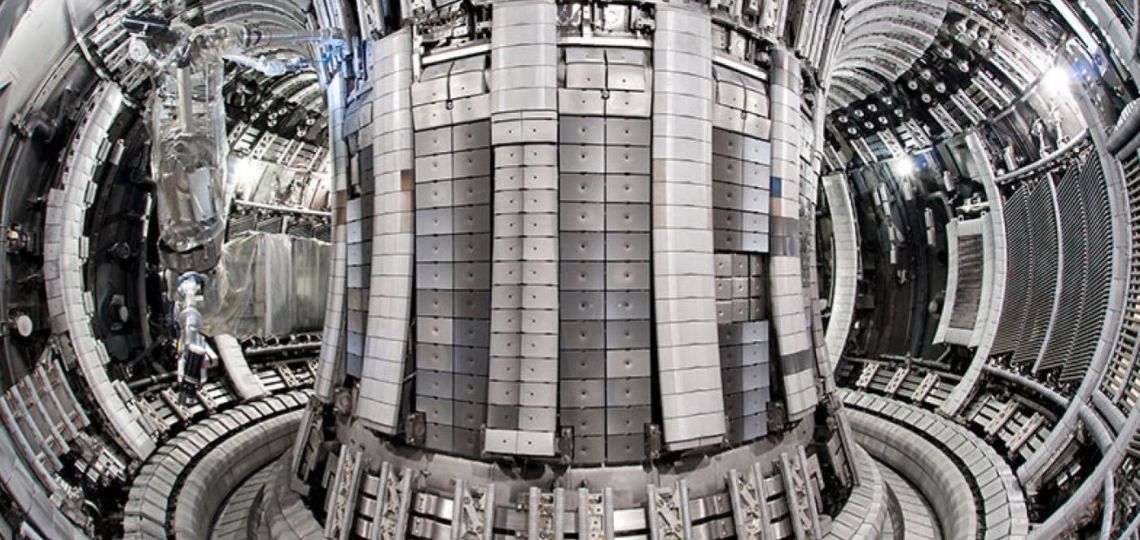

Triple the storage capacity of underwater containers

This first is considered a major step forward. Until now, the country has had only limited space in the single storage basin dedicated to fuel for the Advanced Gas-Cooled Reactor (AGR). Now, the Nuclear Space Saver would save three times as much space in the same Sellafield basin.

A unique solution for storing nuclear fuel from AGR power plants reaching the end of their operational life. The country currently has seven AGR power plants, all operated by EDF Energy.

Andrew Pringle said:

“The current storage compartments can hold up to 20 fuel containers. We knew this wouldn’t be enough. So we worked for several years to come up with a solution. The answer is the Hybrid 1 63-can rack, which, as its name suggests, can store 63 fuel cans in a single rack. The first rack has been installed in the Thorp (Sellafield) reception and storage basin. We have 15 more to follow, and then the Hybrid 2 rack, which is an improved design to optimize manufacturing, will be used to store the fuel cans”.

Energy companies collaborate on nuclear space saver

The project has received contributions from Sellafield, EDF Energy, the NDA Nuclear Decommissioning Authority and Direct Rail Services. A tender for the manufacture of Hybrid 2 design racks has been published on Sellafield Ltd’s CTM system (ref. 12613.) The contract is due to be awarded in August 2021.

This new project is a major opportunity for the nuclear sector, but also for energy companies’ decommissioning projects.