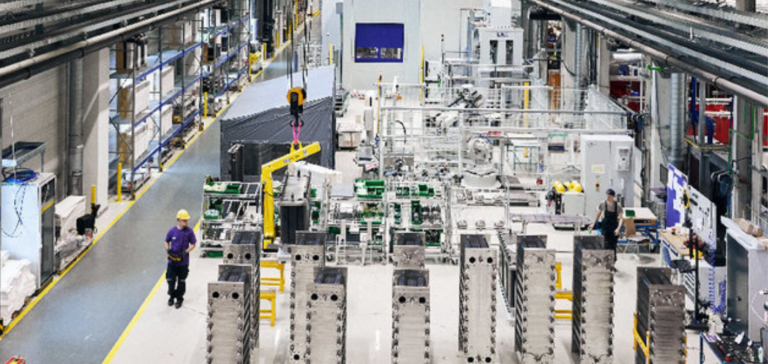

Air Liquide and Siemens Energy have jointly opened their electrolyser gigafactory in Berlin. The plant is located on a 2,000 square meter site in Berlin. Its main vocation is the mass production of proton exchange membrane (PEM) electrolyzer modules. These PEM modules play an essential role in the low-carbon hydrogen production process. They are distinguished by their high degree of efficiency, making them particularly well-suited to managing the intermittent nature of renewable energies.

Ambitious production capacity

The plant, which began operations with a production capacity of one gigawatt, has considerable ambitions, aiming to reach a capacity of three gigawatts by 2025. This gradual ramp-up represents a crucial step towards large-scale hydrogen production. In addition, the installation offers a major advantage: the possibility of assembling the electrolyser modules close to the sites where they will be deployed. This geographical proximity significantly reduces transport and logistics costs, which in turn improves the overall profitability of the production process, reinforcing the viability of the low-carbon hydrogen offer.

Combined Expertise

This strategic partnership between Air Liquide and Siemens Energy builds on their respective expertise. On the one hand, Siemens Energy brings cutting-edge technologies and considerable industrial capacity. On the other, Air Liquide masters the entire hydrogen value chain and develops innovative, tailor-made projects.

Investment in Research and Development

What’s more, the two companies are investing in research and development to co-develop the next generation of electrolyzers. This ensures that the technology remains at the cutting edge of efficiency and durability.

In fact, this partnership also benefits from a number of ongoing hydrogen projects. These projects are under development in various countries, including Germany, France, Denmark and Sweden. Their main objective is to contribute to the decarbonization of various industrial sectors. In addition, these initiatives are designed to encourage the development of synthetic fuels for marine transport.

The inauguration of the Air Liquide and Siemens Energy electrolyser gigafactory in Berlin represents a crucial step towards large-scale low-carbon hydrogen production. This collaboration between two industry leaders paves the way for a more sustainable energy transition in Europe and beyond.