Air Liquide and the Jiangsu Shagang Group are jointly developing a new air separation unit (ASU) in China.

A massive project with multiple impacts, Air Liquide hopes to combine technical innovation, profitability and carbon neutrality.

Air Liquide aims to decarbonize the steel industry

The company is investing nearly 100 million euros in the development of an air separation unit in Zhangjiagang, China.

The project is being carried out in collaboration with China’s largest private steel company, the Jiangsu Shagang Group.

It would be the world’s largest ASU for the steel industry, as well as Air Liquide’s largest ASU in China.

The technology, which will be operational by the end of 2023, should have a daily production capacity of 3,800 tonnes of oxygen.

This new project aims to strengthen the partnership between Air Liquide and the Shagang Group, established in 2007.

A technical innovation for ASUs

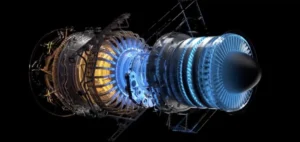

The ASU successively divides the gas supplied to it through a serial cooling process.

First hydrocarbons, then nitrogen and oxygen, and finally noble gases can be extracted by this process.

The technology is also designed to partially recover the energy released by the expanding gas.

The new ASU will be equipped with AliveTM technology, enabling it to store up to 60 MW on a daily basis.

This should enhance network flexibility and contribute to greatergas supply reliability.

A new source of pure gases

This ASU will be a new source of krypton and xenon to meet the growing demand from the electronics industry.

The Zhangjiagang site will also become the company’s largest source of liquid oxygen and nitrogen in China.

Its ultra-pure oxygen capacity positions Air Liquide strategically to support small and medium-sized liquid and packaged gas customers.

In particular, local hospitals requiring high-purity medical gases in eastern China have made contact.

ASU in the service of carbon neutrality

This technology is in line with Air Liquide’s ambitions to exploit the energy transition to develop a new business line.

Supplied with low-carbon energy, the ASU will help reduce the environmental footprint of one of China’s largest industrial sites.

According to Air Liquide, the technology will also enable the Shagang Group to reduce its production costs and energy consumption.

Air Liquide’s technical innovation reflects its ambition to combine innovative solutions with carbon neutrality.

In particular, the two companies aim to explore the decarbonization of steelmaking.